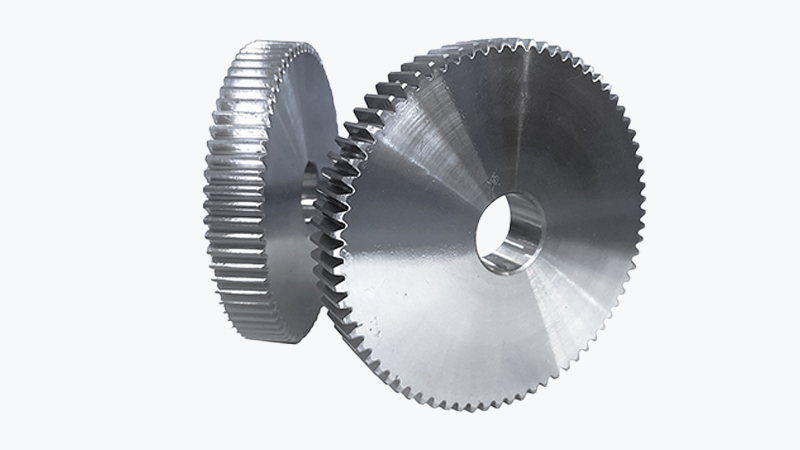

The main factors affecting the accuracy of gear transmission

The main factors affecting the accuracy of gear transmission include: machining accuracy of gears, accuracy level of gears, backlash requirements of gear pairs, and contact spot requirements of gear pairs.

The radial error of gears can generally be reflected by measuring the radial runout △ Fr of the gear ring. The main reasons for the radial error of gears during gear cutting are as follows:

① When adjusting the fixture, the spindle and the center of rotation of the machine tool worktable do not coincide.

② There is a gap between the tooth blank reference hole and the spindle, which tends to tilt to one side during clamping.

③ Poor positioning of the reference end face, resulting in eccentricity of the inner hole relative to the center of rotation of the worktable after clamping.

The tangential error of gears refers to the displacement of the actual tooth profile relative to the theoretical position along the circumferential direction (tangential) during gear hobbing. When the gear experiences tangential displacement, it can be reflected by measuring the variation tolerance △ Fw of the common normal length.

The main cause of gear tangential error during gear cutting is the transmission error of the transmission chain. Among the various transmission components of the toothed transmission chain, the indexing worm gear under the worktable has the greatest impact on transmission errors. The indexing worm gear does not coincide with the center of rotation of the worktable during manufacturing and installation (motion eccentricity), resulting in angular errors during worktable rotation, which are reflected to the gears. Secondly, another important factor affecting transmission errors is the manufacturing and installation errors of the toothed wheel, which are also transmitted to the worktable in a large proportion.